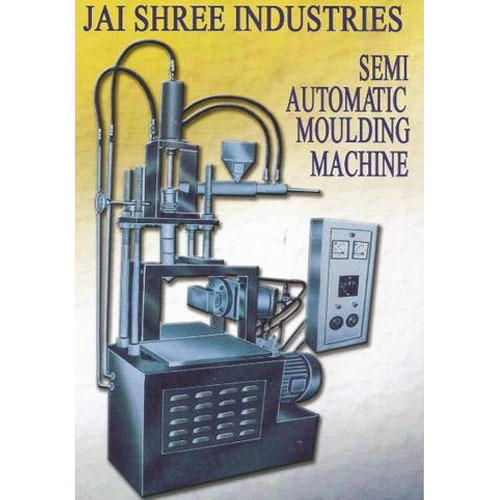

Semi Automatic Piller Type Moulding Machine

To meet variegated requirements of our esteemed clients, all over the world, we present a vast assortment of Semi Automatic Moulding Machine. The offered injection molding machine is inspected by our quality controllers on numerous quality parameters so as to provide a flawless range at customer’s end.

Furthermore, this injection molding machine is obtainable at nominal price in a promised time frame. This injection molding machine is designed by our professionals using contemporary techniques in fulfillment to set industry standards.

Features:

- Air Ejection System

- Hydraulic Ejector System

- Core Pulling Attachment

Other Details:

- Robust Five Point Double Toggle Clamping System Ensures Fast & Accurate Movement For Perfect Mold Lock

- Gas Nitride Wear Resistance Screw Barrel

- High Chrome Plated Step Less Tie Bars

- Steel Fabricated Rigid Machine Base

- Mold Height Gear Wheel Setting

- S.S. Hopper with Magnet Grill

- Operator Safety System & Safety Interlock For Door Operation

- Cold Screw Start Prevention Interlock

- Slow Down Hydraulic Circuit Valve For Power Saving

- Digital Shot Counter & Digital Total Machine Run Timer

- Programmable Logic Control Panel (PLC)

- Three Stage Opening & Closing Speed

- Suck-Buck System For Material Drilling

Optional Features:

- L.P.M.S. System (Low Pressure Mold Safety)

- Servo Drive 50 % to 80 % Energy saving

- Proportional Hydraulics

- Auto Oil Lubrication System

- Hopper Dryer / Dehumidifier

- Hopper Loader

- Mold Temperature Controller

- Core Pulling Attachment

- Air Ejection System

- Hydraulic Ejector System

- Extended Nozzle With Heater

- Water Flow Battery

- Part Drop Detector

- Motorized Hydraulic Mold Height Setting System

Specifications:

- Type: Semi Automatic Moulding Machine

- Power(W): 10kW

- Voltage: 380V/50HZ

- Dimension(L*W*H): 2.5*1.5*2m

- Application: Industrial

- Minimum Order Quantity: 1

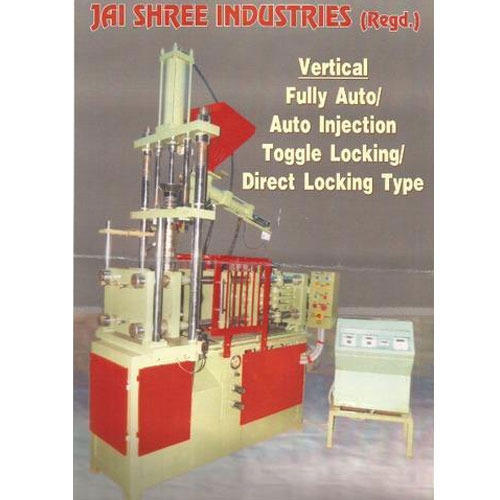

Fully Automatic Vertical Injection Moulding Machine

Minimum Order Quantity: 1 Unit

To meet variegated requirements of our esteemed clients, all over the world, we present a vast assortment of Automatic Plastic Injection Moulding Machine. The offered injection moulding machine is inspected by our quality controllers on numerous quality parameters so as to provide a flawless range at customer’s end. Furthermore, this injection molding machine is obtainable at nominal price in a promised time frame. This injection molding machine is designed by our professionals using contemporary techniques in fulfillment to set industry standards.

Features:

- Air Ejection System

- Hydraulic Ejector System

- Core Pulling Attachment

Other Details:

- Robust Five Point Double Toggle Clamping System Ensures Fast & Accurate Movement For Perfect Mould Lock

- Gas Nitride Wear Resistance Screw Barrel

- High Chrome Plated Step Less Tie Bars

- Steel Fabricated Rigid Machine Base

- Mould Height Gear Wheel Setting

- S.S. Hopper with Magnet Grill

- Operator Safety System & Safety Interlock For Door Operation

- Cold Screw Start Prevention Interlock

- Slow Down Hydraulic Circuit Valve For Power Saving

- Digital Shot Counter & Digital Total Machine Run Timer

- Programmable Logic Control Panel (PLC)

- Three Stage Opening & Closing Speed

- Suck-Buck System For Material Drilling

Optional Features

- L.P.M.S. System (Low Pressure Mold Safety)

- Servo Drive 50 % to 80 % Energy saving

- Proportional Hydraulics

- Auto Oil Lubrication System

- Hopper Dryer / Dehumidifier

- Hopper Loader

- Mould Temperature Controller

- Core Pulling Attachment

- Air Ejection System

- Hydraulic Ejector System

- Extended Nozzle With Heater

- Water Flow Battery

- Part Drop Detector

- Motorized Hydraulic Mould Height Setting System

Specifications:

- Type: Vertical Injection Moulding Machine

- Power(W): 15kW

- Voltage: 360V/50HZ

- Dimension(L*W*H): 2.5*2*3m

- Application: Industrial

- Minimum Order Quantity: 1

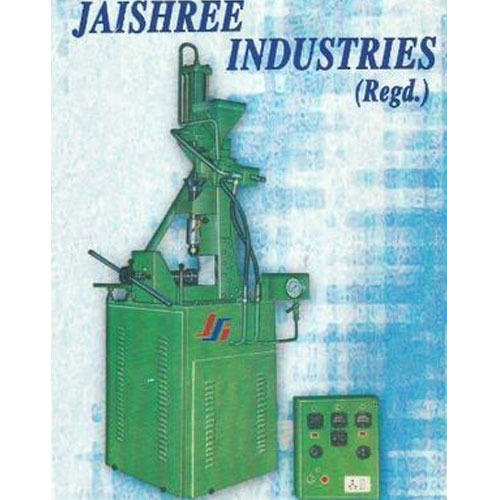

Heavy Duty Injection Moulding Machine

Product Details:

To meet variegated requirements of our esteemed clients, all over the world, we present a vast assortment of Heavy Duty Injection Moulding Machine. The offered injection molding machine is inspected by our quality controllers on numerous quality parameters so as to provide a flawless range at customer’s end. Furthermore, this injection moulding machine is obtainable at nominal price in a promised time frame. This injection moulding machine is designed by our professionals using contemporary techniques in fulfillment to set industry standards.

Features:

- Air Ejection System

- Hydraulic Ejector System

- Core Pulling Attachment

Other Details:

- Robust Five Point Double Toggle Clamping System Ensures Fast & Accurate Movement For Perfect mould Lock

- Gas Nitride Wear Resistance Screw Barrel

- High Chrome Plated Step Less Tie Bars

- Steel Fabricated Rigid Machine Base

- Mould Height Gear Wheel Setting

- S.S. Hopper with Magnet Grill

- Operator Safety System & Safety Interlock For Door Operation

- Cold Screw Start Prevention Interlock

- Slow Down Hydraulic Circuit Valve For Power Saving

- Digital Shot Counter & Digital Total Machine Run Timer

- Programmable Logic Control Panel (PLC)

- Three Stage Opening & Closing Speed

- Suck-Buck System For Material Drilling

Optional Features:

- L.P.M.S. System (Low Pressure Mold Safety)

- Servo Drive 50 % to 80 % Energy saving

- Proportional Hydraulics

- Auto Oil Lubrication System

- Hopper Dryer / Dehumidifier

- Hopper Loader

- Mould Temperature Controller

- Core Pulling Attachment

- Air Ejection System

- Hydraulic Ejector System

- Extended Nozzle With Heater

- Water Flow Battery

- Part Drop Detector

- Motorized Hydraulic Mould Height Setting System

Specifications:

- Type: Heavy Duty Injection Moulding Machine

- Power(W): 30kW

- Voltage: 330V/50HZ

- Dimension(L*W*H): 3*2*3mm

- Application: Industrial

- Minimum Order Quantity: 1

-

Structure : Vertical

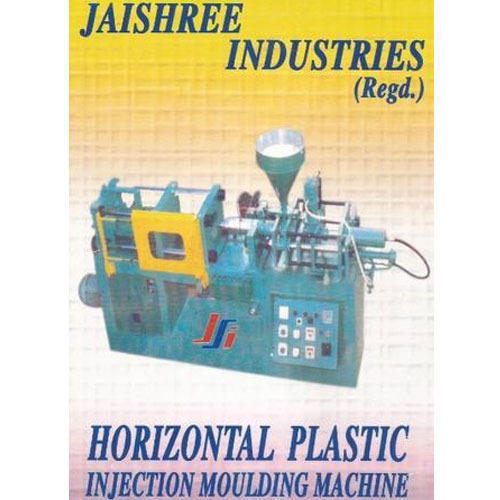

Horizontal Injection Moulding Machine

Product Details:

To meet variegated requirements of our esteemed clients, all over the world, we present a vast assortment of Horizontal Injection Moulding Machine. The offered moulding injection machine is inspected by our quality controllers on numerous quality parameters so as to provide a flawless range at customer’s end. Furthermore, this injection moulding machine is obtainable at nominal price in a promised time frame. This injection moulding machine is designed by our professionals using contemporary techniques in fulfillment to set industry standards.

Features:

- Air Ejection System

- Hydraulic Ejector System

- Core Pulling Attachment

Other Details:

- Robust Five Point Double Toggle Clamping System Ensures Fast & Accurate Movement For Perfect Mould Lock

- Gas Nitride Wear Resistance Screw Barrel

- High Chrome Plated Step Less Tie Bars

- Steel Fabricated Rigid Machine Base

- Mold Height Gear Wheel Setting

- S.S. Hopper with Magnet Grill

- Operator Safety System & Safety Interlock For Door Operation

- Cold Screw Start Prevention Interlock

- Slow Down Hydraulic Circuit Valve For Power Saving

- Digital Shot Counter & Digital Total Machine Run Timer

- Programmable Logic Control Panel (PLC)

- Three Stage Opening & Closing Speed

- Suck-Buck System For Material Drilling

Optional Features:

- L.P.M.S. System (Low Pressure Mould Safety)

- Servo Drive 50 % to 80 % Energy saving

- Proportional Hydraulics

- Auto Oil Lubrication System

- Hopper Dryer / Dehumidifier

- Hopper Loader

- Mould Temperature Controller

- Core Pulling Attachment

- Air Ejection System

- Hydraulic Ejector System

- Extended Nozzle With Heater

- Water Flow Battery

- Part Drop Detector

- Motorized Hydraulic Height Setting System

Specifications:

- Type: Horizontal Injection Moulding Machine

- Power(W): 20kW

- Voltage: 320V/50HZ

- Dimension(L*W*H): 2*3*2mm

- Application: Industrial

- Minimum Order Quantity: 1

Fully Automatic Injection Moulding Machine

Minimum Order Quantity: 1 Unit

To meet variegated requirements of our esteemed clients, all over the world, we present a vast assortment of Automatic Plastic Injection Moulding Machine. The offered injection moulding machine is inspected by our quality controllers on numerous quality parameters so as to provide a flawless range at customer’s end. Furthermore, this injection moulding machine is obtainable at nominal price in a promised time frame. This injection moulding machine is designed by our professionals using contemporary techniques in fulfillment to set industry standards.

Features:

- Air Ejection System

- Hydraulic Ejector System

- Core Pulling Attachment

Other Details:

- Robust Five Point Double Toggle Clamping System Ensures Fast & Accurate Movement For Perfect Mould Lock

- Gas Nitride Wear Resistance Screw Barrel

- High Chrome Plated Step Less Tie Bars

- Steel Fabricated Rigid Machine Base

- Mould Height Gear Wheel Setting

- S.S. Hopper with Magnet Grill

- Operator Safety System & Safety Interlock For Door Operation

- Cold Screw Start Prevention Interlock

- Slow Down Hydraulic Circuit Valve For Power Saving

- Digital Shot Counter & Digital Total Machine Run Timer

- Programmable Logic Control Panel (PLC)

- Three Stage Opening & Closing Speed

- Suck-Buck System For Material Drilling

Optional Features:

- L.P.M.S. System (Low Pressure Mould Safety)

- Servo Drive 50 % to 80 % Energy saving

- Proportional Hydraulics

- Auto Oil Lubrication System

- Hopper Dryer / Dehumidifier

- Hopper Loader

- Mould Temperature Controller

- Core Pulling Attachment

- Air Ejection System

- Hydraulic Ejector System

- Extended Nozzle With Heater

- Water Flow Battery

- Part Drop Detector

- Motorized Hydraulic Mould Height Setting System

Industrial Injection Moulding Machine

Minimum Order Quantity: 1 Unit

To meet variegated requirements of our esteemed clients, all over the world, we present a vast assortment of Industrial Injection Moulding Machine. The offered injection moulding machine is inspected by our quality controllers on numerous quality parameters so as to provide a flawless range at customer’s end. Furthermore, this injection moulding machine is obtainable at nominal price in a promised time frame. This injection moulding machine is designed by our professionals using contemporary techniques in fulfillment to set industry standards.

Features:

- Air Ejection System

- Hydraulic Ejector System

- Core Pulling Attachment

Other Details:

- Robust Five Point Double Toggle Clamping System Ensures Fast & Accurate Movement For Perfect Mould Lock

- Gas Nitride Wear Resistance Screw Barrel

- High Chrome Plated Step Less Tie Bars

- Steel Fabricated Rigid Machine Base

- Mould Height Gear Wheel Setting

- S.S. Hopper with Magnet Grill

- Operator Safety System & Safety Interlock For Door Operation

- Cold Screw Start Prevention Interlock

- Slow Down Hydraulic Circuit Valve For Power Saving

- Digital Shot Counter & Digital Total Machine Run Timer

- Programmable Logic Control Panel (PLC)

- Three Stage Opening & Closing Speed

- Suck-Buck System For Material Drilling

Optional Features:

- L.P.M.S. System (Low Pressure Mold Safety)

- Servo Drive 50 % to 80 % Energy saving

- Proportional Hydraulics

- Auto Oil Lubrication System

- Hopper Dryer / Dehumidifier

- Hopper Loader

- Mould Temperature Controller

- Core Pulling Attachment

- Air Ejection System

- Hydraulic Ejector System

- Extended Nozzle With Heater

- Water Flow Battery

- Part Drop Detector

- Motorized Hydraulic Mould Height Setting System

Specifications:

- Type: Industrial Injection Moulding Machine

- Power(W): 30kW

- Voltage: 330V/50HZ

- Dimension(L*W*H): 2*3*2mm

- Application: Industrial

- Minimum Order Quantity: 1

Copyright © 2010-2021 Jai Shree Industries (Regd.). All Rights Reserved Powered by IT NUCLEUS